Description

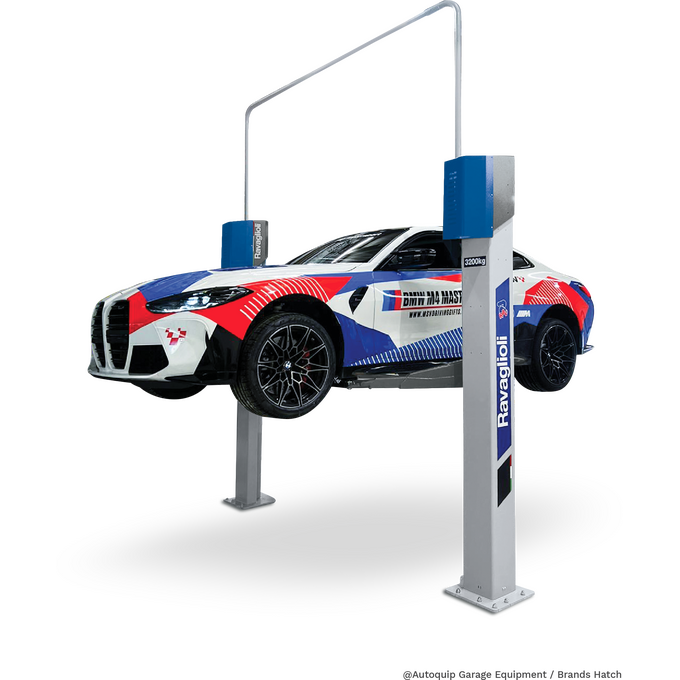

Legend Series – From History to the Future

- Up-to-date design: modern outline that brings modernity and usability to the workshop

- Innovative DNA: long-standing high-quality components and tested for 20000 cycles

- Future-proof: lifts designed for the TEq-Link workshop connectivity system

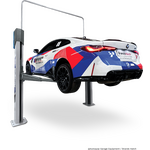

Emerging from the bestselling 2-post lifts, the Legend Series consolidates the engineering knowledge of Ravaglioli and shapes it into an innovative package. Looking towards the future while always honouring the past, Ravaglioli has set an important goal for itself – let the performance meet the design.

- Minimum routine maintenance: The operating parts require little time for easy replacement or maintenance reducing the risk of error on safety elements.

- Guaranteed safety and quality over the time: The lift is equipped with premium components that guarantee durability and maximum safety for the operator.

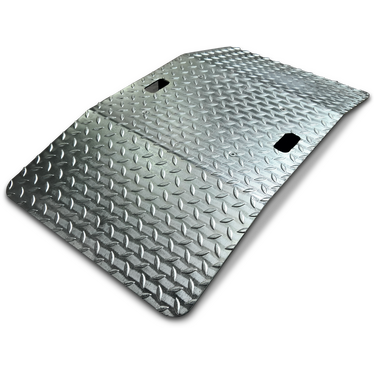

- Smart and flexible installation – Up to 20% improvement in installation time: The electronic synchronization avoids the installation and adjustment of the realignment cable. The lifts can be installed in a flexible way thanks to three width-adjustable positions.

- Quick and easy operations: The working bay is free of obstacles and the operations can be performed safely and comfortably.

- A step into the future: Selected models with integrated TEq-Link module which enables to monitor work cycles, trigger alerts for scheduled maintenance and more.

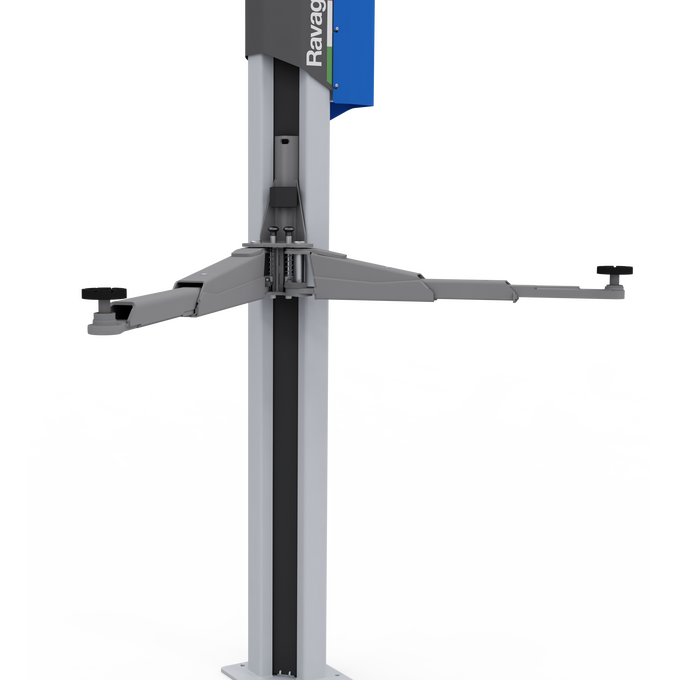

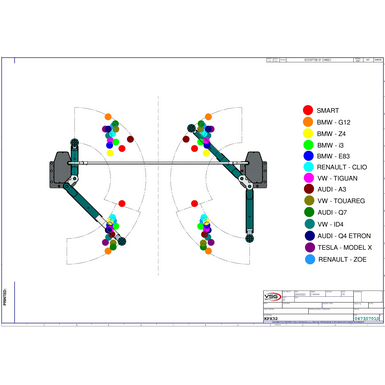

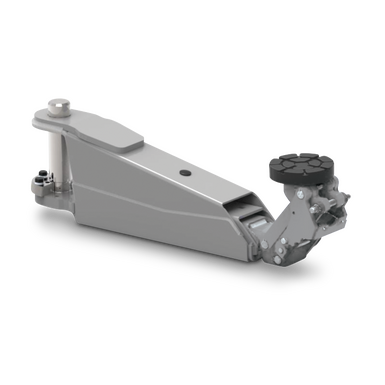

- The geometry of the arms was designed to lift anything from city to long wheelbase cars.

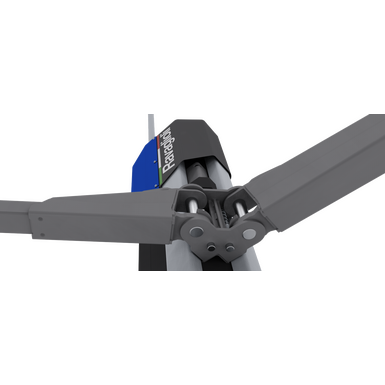

- Rotated electromechanical lift featuring columns at 45°.

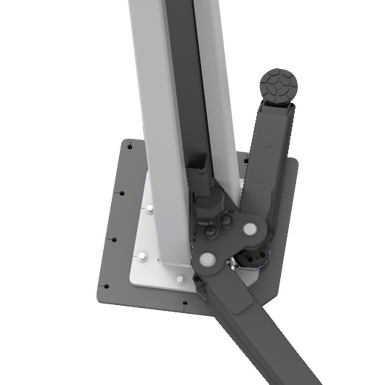

- Push bottons control (up/down) at an ergonomic height.

- Easy door opening: The vehicle can be placed backward without any worries about damaging.

- Thanks to the asymmetric design of the columns, the loading areas of the arms overlap, granting great flexibility and time saving when picking up the vehicle.

- More space for movement around the vehicle: The lift is designed to maximise its layout while ensuring minimum space requirements.

- Quick car positioning: The operator has at his disposal a wide loading area, without the necessity of pushing and pulling the vehicle to find the right lifting position.

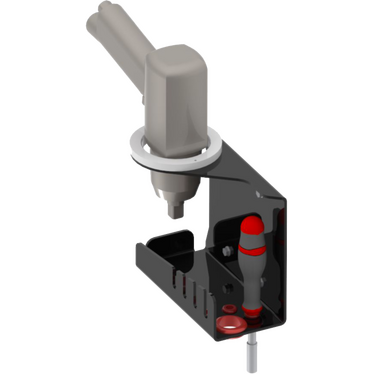

- Electronic synchronization

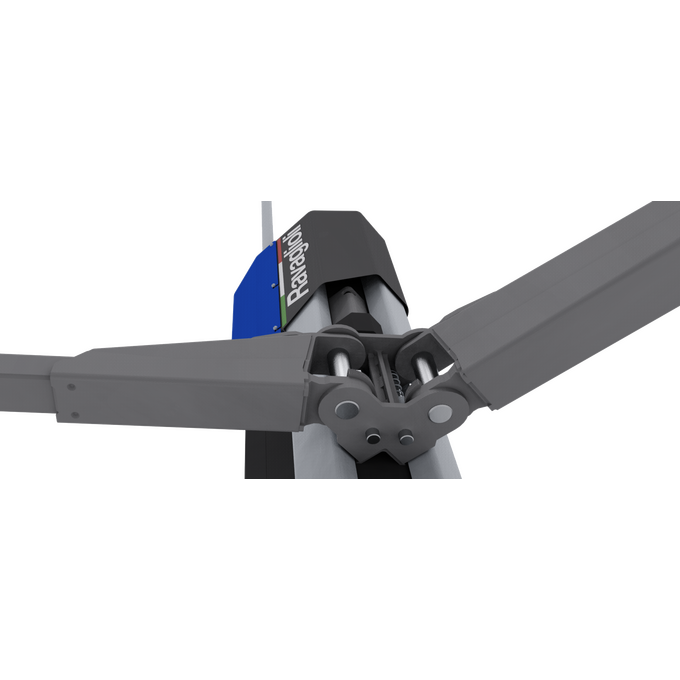

- Quick nut replacing: New motor plate that allows to remove the screw from the front side of the column with the column standing.

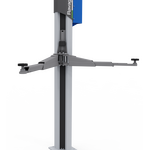

- Internal carriages running on lubricated sliding guides, protected from the external environment, that ensures a longer life to the sliding elements

- Energy kit

- Equipped with an acoustic anti-toe trap system – Free from mechanical foot guards

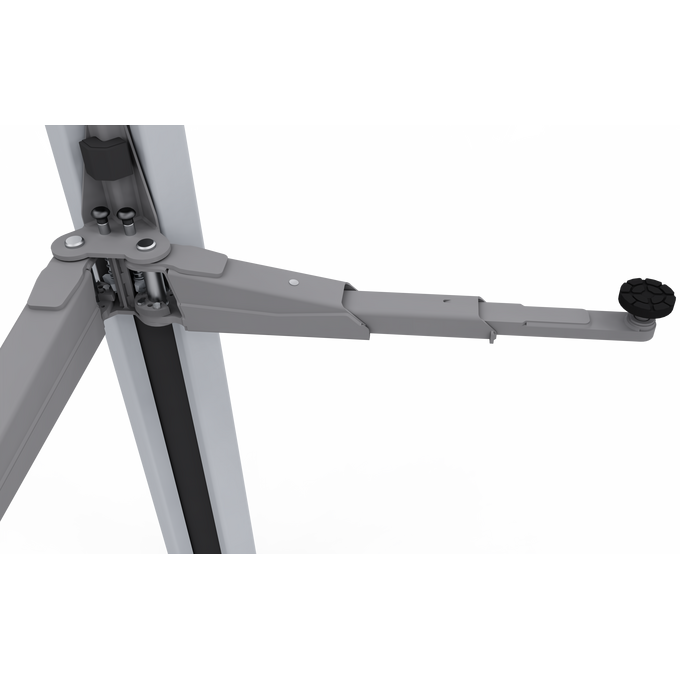

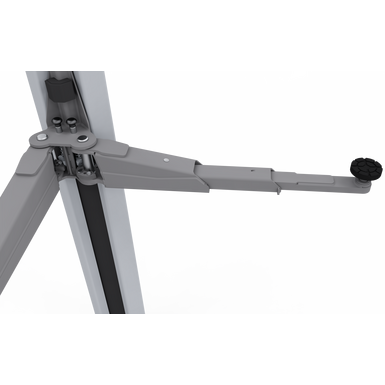

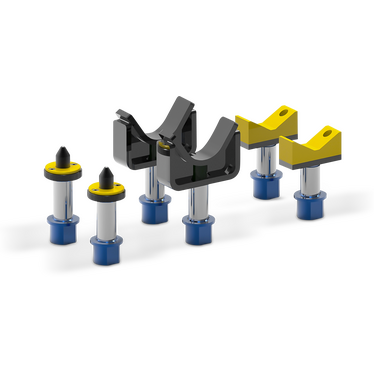

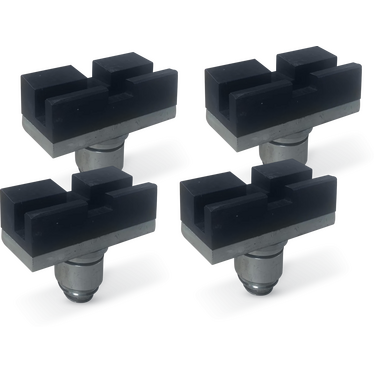

- Short 3-stage arms and long 2-stage arms with quick fit telescopic rubber pad

- Truly asymmetric columns designed to optimize the drive through and footprint

- Premium quality of components

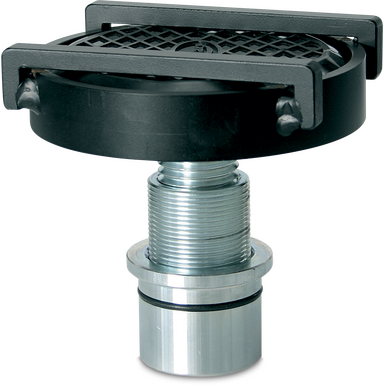

- Aluminium pulley with cooling function

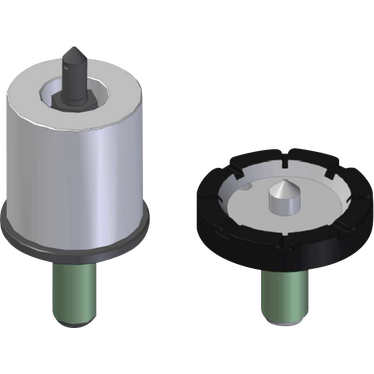

- Long-lasting bearings

- 50% longer, bronze load nut

- Motors with reinforced and cooling casing

- Solid automatic arm locking